Understanding the Fundamental Role of Burrs in Coffee Grinding

Coffee burrs are the heart and soul of every quality coffee grinder, serving as the mechanism that transforms whole beans into brewable grounds. Unlike blade grinders that chop beans haphazardly, burrs crush coffee beans between two abrasive surfaces with precisely engineered patterns, creating grounds that are remarkably consistent in size.

This consistency isn’t just about aesthetics—it’s absolutely critical for proper extraction. When coffee grounds are uniform in size, water interacts with them evenly during brewing, extracting flavors in a balanced way. The precision grind settings used in quality grinders directly influence every aspect of your coffee experience:

- Even extraction of flavor compounds

- Balanced acidity and sweetness

- Proper brewing flow rate

- Repeatable results cup after cup

High-quality manual coffee burr grinders have become essential tools for coffee enthusiasts who understand that grind uniformity represents the difference between an exceptional cup and a mediocre one. In blind taste tests, coffee made with consistent grounds consistently outperforms those made with irregular particles—even when using identical beans and brewing methods.

Throughout this guide, we’ll explore the science behind burr design and how these precision instruments affect every aspect of your coffee brewing journey.

The Science of Coffee Extraction: Why Uniformity Is Non-Negotiable

Coffee extraction is fundamentally a chemical process where water dissolves and pulls flavor compounds from ground coffee particles. The size of these particles directly determines how quickly and completely this extraction happens—making uniformity absolutely essential.

When water meets coffee grounds, it doesn’t extract all flavor compounds at once. Instead, there’s a specific sequence:

1. Acids and fruity notes extract first (early extraction)

2. Sweetness and balanced flavors extract in the middle phase

3. Bitter compounds and astringency extract last (later extraction)

This is where particle uniformity becomes crucial. With inconsistent grounds, small particles (fines) over-extract while large particles (boulders) under-extract simultaneously. This creates coffee that is paradoxically both bitter and sour—an unpleasant combination that masks the bean’s true character.

The science backs this up: optimal coffee extraction typically falls between 18-22% of the coffee’s mass being dissolved into the water. Inconsistent grinding makes it virtually impossible to hit this target extraction percentage, as different-sized particles extract at wildly different rates.

Understanding espresso grind settings becomes particularly important because the pressurized brewing method amplifies any inconsistencies in the coffee bed. Even small variations in particle size can create channeling—where water finds the path of least resistance through the coffee puck, resulting in uneven extraction.

Conical vs. Flat Burrs: Breaking Down the Two Primary Designs

When exploring the world of quality coffee grinders, you’ll encounter two predominant burr designs: conical and flat. Each offers distinct advantages and creates different grinding characteristics that influence your final cup.

Conical Burrs feature a cone-shaped inner burr that fits inside a ring-shaped outer burr. As beans enter the wider upper portion, they’re gradually crushed into smaller particles as they move down the narrowing gap. This design:

– Produces a slightly bimodal particle distribution (more fines and coarse particles)

– Generally generates less heat during grinding

– Tends to be more forgiving with alignment issues

– Creates a flavor profile often described as having more body and texture

Flat Burrs consist of two parallel rings with grinding surfaces facing each other. Coffee beans enter through the center and are crushed as they move outward between the rings. This design:

– Creates a more unimodal particle distribution (more particles clustered around the target size)

– Typically provides exceptional clarity in flavor notes

– May generate slightly more heat during extended grinding

– Usually requires more precise alignment for optimal performance

Many coffee enthusiasts find that flat burr hand grinders excel at highlighting bright, nuanced flavors in light to medium roasts, particularly for pour-over brewing methods.

| Feature | Conical Burrs | Flat Burrs |

|---|---|---|

| Particle Distribution | Bimodal (more variance) | Unimodal (more consistent) |

| Heat Generation | Lower | Moderate |

| Grind Retention | Low to moderate | Moderate to higher |

| Flavor Emphasis | Body and richness | Clarity and brightness |

| Typical Use Cases | Versatile, espresso | Pour-over, filter methods |

Burr Size Matters: How Diameter Affects Grinding Performance

The diameter of coffee grinder burrs significantly impacts performance in ways that directly affect your brewing experience. Understanding this relationship helps you make informed decisions when investing in grinding equipment.

Larger burr diameters provide several tangible benefits:

Increased grinding speed: Larger burrs have more cutting surface area, processing beans more efficiently. A 64mm burr set might grind a dose for espresso in 8-10 seconds, while a 38mm set could take 25-30 seconds for the same amount.

Improved heat management: Larger burrs distribute grinding friction across a bigger surface area, reducing heat buildup that can negatively affect flavor compounds in coffee beans.

Enhanced grind consistency: The increased surface area and typically more sophisticated cutting geometry of larger burrs often results in more uniform particle size distribution.

Finer adjustment capability: Many grinders with larger burrs offer more precise adjustment mechanisms, allowing for subtle tweaks that can dramatically improve extraction.

Common burr sizes in quality home grinders include:

| Burr Size | Typical Application | Grinding Speed |

|---|---|---|

| 38mm | Entry-level manual grinders | Moderate |

| 48mm | Mid-range manual/electric | Good |

| 55mm | Prosumer electric grinders | Very good |

| 64mm | Professional/high-end home | Excellent |

| 68-98mm | Commercial/ultra-premium | Outstanding |

The impact of burr diameter on coffee grind becomes particularly noticeable when working with light roasts or when grinding for espresso, where consistency and precision are paramount. Many coffee enthusiasts find that precision manual grinders with larger burrs provide exceptional value, combining quality construction with outstanding grind performance.

Beyond Size: How Burr Material Impacts Grind Quality and Longevity

The material composition of your coffee grinder’s burrs dramatically affects both performance and lifespan, making it a crucial factor to consider alongside size and geometry.

Steel Burrs

– Provide exceptional sharpness and cutting precision

– Typically offer superior particle size consistency

– May transfer minimal heat during grinding

– Generally last 500-1500 pounds of coffee before replacement

– Excel at creating clean, clear flavor profiles

– Standard in most high-performance grinders

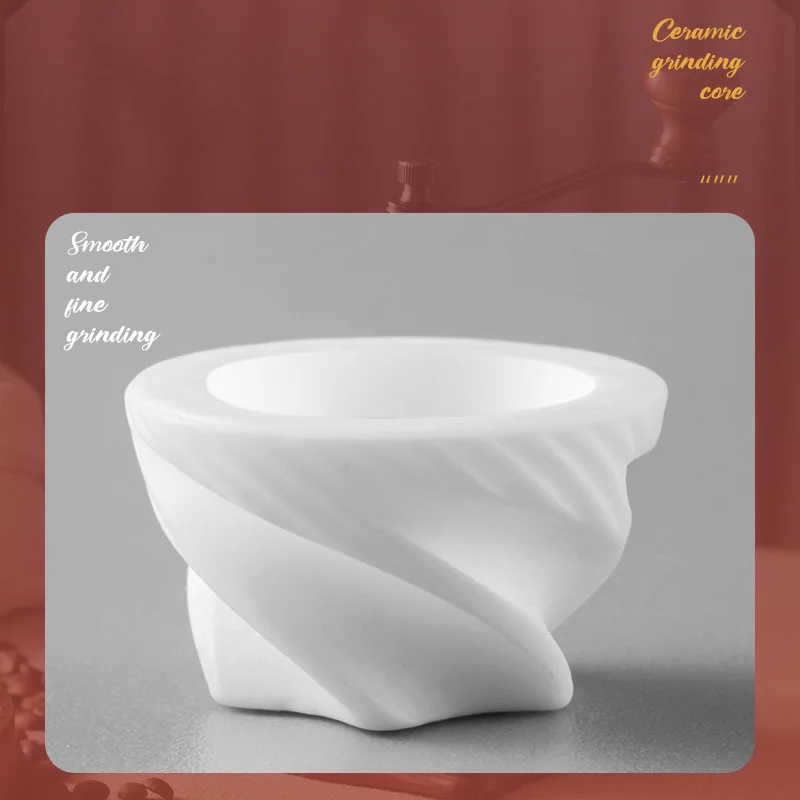

Ceramic Burrs

– Stay sharper longer than steel with proper care

– Transfer less heat during grinding

– May chip if foreign objects enter the grinder

– Can potentially last 1000-2000+ pounds of coffee

– Often found in ceramic burr coffee grinders designed for longevity

– Tend to produce slightly more fines than premium steel

Titanium-Coated Burrs

– Feature enhanced hardness and wear resistance

– Maintain sharpness significantly longer than standard steel

– Typically last 1500-2500 pounds of coffee

– Command a premium price for their longevity

– Often found in commercial or prosumer equipment

– May offer enhanced clarity in flavor profiles

Specialized Coatings

– TiN (titanium nitride) provides gold-colored coating with enhanced durability

– DLC (diamond-like carbon) offers exceptional hardness and reduced friction

– Red Speed or SSP treatments modify surface characteristics for performance

– Generally add 30-50% to burr lifespan while reducing retention

When choosing between materials, consider your brewing volume, preferred coffee styles, and budget. Light roast enthusiasts who appreciate bright, complex flavors often prefer high-quality steel burrs, while those seeking maximum longevity might opt for ceramic or coated options.

Burr Geometry: The Hidden Factor in Grind Uniformity

Beyond size and material, the specific tooth design and cutting pattern of coffee burrs dramatically influence grind quality. This often-overlooked aspect of burr design can make a substantial difference in extraction consistency and flavor clarity.

Modern burr geometry typically features three distinct zones working in sequence:

The Feed Zone – The upper portion where whole beans initially enter the grinding chamber. Its primary purpose is to guide beans toward the crushing surfaces while breaking them into manageable pieces.

The Crushing Zone – The middle section where most size reduction occurs. Here, beans are progressively broken down as they travel through decreasing clearances between the burrs.

The Exit Zone – The final portion where fine-tuning of particle size occurs. This zone’s design significantly impacts uniformity and determines the final size distribution profile.

The specific tooth pattern within each zone greatly affects performance:

- Aggressive teeth in the feed zone improve bean intake speed but may create more fines

- Progressive tooth design gradually reduces particle size for improved consistency

- Fine-pitched patterns in the exit zone enhance uniformity but may slow grinding

- Hybrid designs optimize each zone for specific brewing methods

The impact of burr shape on espresso consistency is particularly notable, as minor variations in geometry can dramatically affect flow rate and extraction evenness. Specialty burrs designed specifically for espresso often feature unique tooth geometries that minimize fines production while maintaining the necessary particle size range.

Manufacturing precision also plays a crucial role—even perfectly designed burrs will perform poorly if machining tolerances are loose or alignment is imprecise. Premium burrs typically feature tighter manufacturing tolerances and more sophisticated cutting geometries that result in noticeably improved cup quality.

Optimizing Grind Uniformity for Different Brewing Methods

Each brewing method extracts coffee differently, requiring specific grind sizes and uniformity characteristics to achieve optimal results. Understanding these requirements helps you adjust your grinder appropriately and maximize flavor extraction.

| Brewing Method | Ideal Grind Size | Uniformity Importance | Common Issues From Poor Uniformity |

|---|---|---|---|

| Espresso | Extra Fine (like fine sand) | Critical | Channeling, uneven extraction, inconsistent shot times |

| Pour Over | Medium-Fine (between table salt and fine sand) | Very High | Uneven drawdown, muddy cup, astringency |

| French Press | Coarse (like sea salt) | Moderate | Excessive sediment, muddiness, bitter finish |

| AeroPress | Fine to Medium (adaptable) | High | Inconsistent pressure needed, uneven extraction |

| Cold Brew | Extra Coarse | Low to Moderate | Extended steep time masks some inconsistency |

| Moka Pot | Fine (slightly coarser than espresso) | High | Channeling, bitter results, inconsistent brew times |

| Drip Coffee | Medium | Moderate to High | Uneven extraction, inconsistent strength |

| Turkish Coffee | Ultra Fine (like flour) | Critical | Inability to achieve proper suspension, gritty texture |

For espresso brewing, the ultimate espresso grind size chart can provide precise guidance for dialing in your shots. The extremely high pressure and short contact time in espresso makes it particularly sensitive to grind uniformity issues.

When using pour-over methods, uniform medium-fine grounds ensure even water flow through the coffee bed, resulting in balanced extraction. With French press, a consistent coarse grind prevents over-extraction during the long steep time while minimizing the amount of fine sediment in your cup.

Quality hand burr grinders allow precise adjustment between these grind sizes, often providing better uniformity than entry-level electric grinders at similar price points.

Signs of Poor Grind Uniformity and How to Identify Them

Recognizing the indicators of inconsistent grinding helps you troubleshoot brewing issues and determine when maintenance or equipment upgrades might be necessary. Here are key signs to watch for:

Visual Indicators:

– Noticeable particles of significantly different sizes when examining grounds

– Excessive dust or powder mixed with larger particles

– Inconsistent color distribution throughout the ground coffee

– Clumping that doesn’t break apart easily when touched

Brewing Indicators:

– Dramatically different extraction times between brews using identical settings

– Water channeling through espresso pucks (creating “mouse holes” or spurting)

– Uneven drawdown in pour-over brewing (water draining faster on one side)

– Simultaneously sour and bitter flavors in the same cup

Taste Indicators:

– Sharp astringency or drying sensation on the palate

– Contradictory flavor notes (both under and over-extracted characteristics)

– Muddled or undefined flavor clarity

– Inconsistent results between brews of the same coffee

Simple Home Test Methods:

1. The Pinch Test: Take a pinch of grounds between your fingers—it should feel consistent in texture without obvious large chunks or powder.

The Paper Test: Spread a small amount of grounds on white paper and examine under good lighting—look for obvious size variations.

The Glass Test: Place grounds in clear water and stir gently—fines will cloud the water while boulders will sink quickly.

The Extraction Test: Brew coffee and taste specifically for simultaneous sourness and bitterness—a classic sign of inconsistent particle size.

Regular manual burr grinder maintenance significantly improves grind consistency and extends the life of your equipment.

Essential Maintenance to Preserve Burr Performance and Uniformity

Proper maintenance of your coffee grinder ensures continued grind uniformity, extends burr life, and preserves flavor quality. Establishing a regular care routine prevents performance degradation and helps you avoid premature replacement costs.

Daily Maintenance:

– Brush out loose grounds from the grinding chamber after each use

– Wipe down the exterior and collection bin to prevent oil buildup

– Keep the grinder in a dry environment to prevent moisture damage

– Leave the hopper empty when not in use to prevent bean staleness

Weekly Maintenance:

– Perform a deeper clean of the burr chamber using a soft brush

– Remove any compacted coffee from adjustment threads and mechanisms

– Check alignment by examining wear patterns on the burrs

– Clean the hopper thoroughly to remove coffee oils

Monthly Maintenance:

– Disassemble the grinding chamber for complete cleaning

– Use grinder-safe cleaning products to remove coffee oils and residue

– Inspect burrs for signs of wear or damage

– Check and tighten any loose components

– Calibrate the grinder to ensure consistent results

Signs Burrs Need Replacement:

– Visibly dull or chipped cutting edges

– Significantly increased grinding time

– Inability to achieve consistent particle size

– Excessive heat generation during grinding

– Dramatically decreased flavor quality despite proper technique

Proper cleaning not only maintains grind quality but also prevents the development of rancid flavors from old coffee oils. For those seeking maximum longevity from their equipment, following a structured maintenance schedule is essential.

Troubleshooting Common Burr Grinder Issues Affecting Uniformity

Even well-maintained grinders can develop performance issues that affect grind consistency. Identifying and addressing these problems promptly helps maintain optimal extraction quality and flavor clarity.

Static Electricity Problems:

– Symptom: Grounds clinging to surfaces and difficult to handle

– Solution: Apply 1-2 drops of water to beans before grinding (RDT method)

– Prevention: Maintain appropriate humidity levels where you store your grinder

Excessive Fines Production:

– Symptom: Muddy cup flavor, clogged filters, slow drawdown

– Solution: Check burr alignment and ensure proper calibration

– Prevention: Adjust your grind more gradually rather than making large changes

Inconsistent Grind Size:

– Symptom: Varying particle sizes despite consistent settings

– Solution: Check for burr wobble, bearing wear, or loose components

– Prevention: Handle grinder gently and avoid dropping or jarring

Bean Feeding Issues:

– Symptom: Stuttering grinding or inconsistent output

– Solution: Clean feed chute thoroughly and check for obstructions

– Prevention: Avoid oily beans that can clog feeding mechanisms

Adjustment Drift:

– Symptom: Grinder setting changes during operation

– Solution: Tighten locking mechanisms and check for worn adjustment threads

– Prevention: Make adjustments gradually and verify settings regularly

Excessive Retention:

– Symptom: Old grounds mixing with fresh, inconsistent flavor

– Solution: Implement purging routine (discarding first few grams after adjustment)

– Prevention: Consider single-dosing workflow to minimize retention

Many uniformity issues can be resolved through proper technique and maintenance rather than requiring equipment replacement. For espresso specifically, even minor adjustments can dramatically improve extraction quality and flavor consistency.

Fine Adjustment Hand Grinder, Precision Manual Grinder, Travel Coffee Grinder

Price range: $185.11 through $494.63 Select options This product has multiple variants. The options may be chosen on the product pageHand Burr Grinder, Hand Crank Coffee Grinder, Manual Espresso Grinder, Portable Coffee Grinder

Price range: $262.72 through $300.22 Select options This product has multiple variants. The options may be chosen on the product pageManual Burr Mill, Manual Coffee Grinder Stainless Steel, Manual Coffee Mill Grinder, Mechanical Coffee Grinder

Price range: $127.26 through $130.32 Select options This product has multiple variants. The options may be chosen on the product pageHand Burr Grinder, Manual Coffee Grinder Stainless Steel, Precision Manual Grinder

Price range: $183.64 through $187.52 Select options This product has multiple variants. The options may be chosen on the product page

How to Choose the Right Burr Grinder for Your Coffee Journey

Selecting a grinder that delivers the uniformity you need requires understanding how different features translate to real-world performance. Here’s how to navigate the options and find the perfect match for your brewing needs.

Match the Grinder to Your Primary Brewing Method:

– For espresso, prioritize stepless adjustment and fine-tuning capability

– For pour-over, look for consistent medium grinding performance

– For multiple brewing methods, seek versatile grinders with wide adjustment ranges

– For travel, consider compact espresso coffee hand grinders that don’t compromise on burr quality

Key Quality Indicators:

– Burr size and material appropriate for your volume and brewing style

– Minimal grind retention to prevent flavor contamination

– Solid construction that resists vibration and maintains alignment

– Repeatable, precise adjustment mechanism

– Stable grinding performance without overheating

Manual vs. Electric Considerations:

– Manual grinders often deliver better grind quality per dollar spent

– Electric grinders offer convenience but may sacrifice uniformity at lower price points

– High-quality manual grinders can match or exceed mid-range electric options for uniformity

– Consider your daily volume and time constraints when choosing between types

| Price Range | What to Expect | Suitable For |

|---|---|---|

| $40-100 | Entry-level burrs, acceptable uniformity for basic brewing | Casual brewing, drip coffee |

| $100-200 | Better burr materials, improved uniformity | Daily brewing, basic espresso |

| $200-400 | Premium burr design, excellent uniformity | Multiple brewing methods, quality espresso |

| $400+ | Top-tier burrs, exceptional uniformity | Enthusiast/professional use, precision brewing |

When evaluating manufacturer claims, focus on burr material and design rather than marketing language. Terms like “precision grinding” mean little without supporting details about burr quality, adjustment mechanisms, and construction materials.

Understanding the differences between burr grinders vs. regular grinders helps clarify why investing in quality burrs makes such a dramatic difference in your brewing results.

FAQs: Common Questions About Coffee Burrs and Grind Uniformity

Can coffee burrs be sharpened instead of replaced?

While technically possible, burr sharpening is generally not practical for home users. The complex geometry of modern burrs requires specialized equipment to maintain precise angles and surfaces. Most manufacturers recommend replacement instead, as even professional resharpening rarely restores original performance.

How often should burrs be replaced for optimal performance?

For home users, burr replacement typically depends on volume rather than time. Steel burrs generally maintain good performance for 500-1000 pounds of coffee, while ceramic burrs may last 1000-2000+ pounds with proper care. Signs that replacement is needed include visibly worn cutting edges, significantly increased grinding time, and inability to achieve consistent particle sizes.

Are expensive grinders always better for uniformity?

Not necessarily. While higher-end grinders generally offer better performance, there are excellent mid-range options that provide outstanding uniformity. The quality of the burrs themselves, alignment precision, and motor stability often matter more than overall cost. Some manual grinders around $200 can outperform electric models costing twice as much in terms of grind consistency.

Can a good grinder handle multiple brewing methods from espresso to French press?

Yes, but with some limitations. High-quality grinders can produce consistent grounds across a wide range of sizes, but those optimized for espresso may sacrifice some performance at coarser settings, and vice versa. The best all-around grinders feature burrs designed for versatility rather than specializing in a single brewing method.

Does burr seasoning actually improve performance?

There is evidence that initial burr seasoning (running several pounds of coffee through new burrs) helps smooth microscopic manufacturing irregularities and improves uniformity. However, claims about dramatic performance improvements are often overstated. Seasoning primarily helps burrs reach their designed performance level rather than enhancing it beyond specifications.

How does roast level affect grind uniformity?

Roast level significantly impacts grinding behavior. Lighter roasts are harder and more dense, requiring more force to grind and potentially producing more fines. Darker roasts are more brittle and contain more oils that can affect grind consistency and potentially cause clumping. Quality grinders handle this variation better, but adjustments are often needed when changing between significantly different roast levels.