Introduction: The Heat Factor in Coffee Grinding

Coffee enthusiasts know that proper grinding is the foundation of exceptional coffee. When beans transform from whole to ground, they release complex flavors and aromas that define your brewing experience. However, this crucial process involves friction, and friction creates heat—a factor that can significantly influence your coffee’s taste profile.

Heat is a silent modifier of coffee chemistry. As temperature rises during grinding, it can potentially alter or degrade certain volatile compounds responsible for the distinctive aromas and flavors that make each coffee unique. These delicate compounds—particularly aromatics like aldehydes—are highly temperature-sensitive and can dissipate or change when exposed to excess heat.

The material of your grinder’s burrs plays a pivotal role in how heat is generated, retained, and transferred to your precious coffee grounds. Steel and ceramic, the two predominant materials used in quality burr grinders, handle heat very differently due to their inherent physical properties.

This article delves into the science behind heat retention in both steel and ceramic burrs, analyzing which material might offer superior heat management for preserving your coffee’s optimal flavor profile. Understanding these differences helps you make more informed decisions about ceramic vs steel burr coffee grinders and their impact on your brewing results.

The Science of Heat Generation During Coffee Grinding

Friction: The Primary Heat Source

When coffee beans meet burrs, the resulting friction converts kinetic energy into thermal energy. This is the primary source of heat during grinding. As beans are crushed and cut between the burrs’ surfaces, tiny particles rub against both the burrs and each other, generating heat through friction. The finer you grind, the more friction occurs, leading to higher temperatures.

Motor Heat Transfer

In electric grinders, a secondary heat source comes from the motor itself. As motors operate, they produce heat that can transfer to the grinding chamber, especially during extended use. This factor is less relevant in manual grinders but becomes significant in high-volume electric grinding scenarios.

The measurable temperature increase during grinding is notable. Testing shows that grinder burrs can rise from room temperature to 100-140°F (38-60°C) during extended grinding sessions. This heat increase isn’t just a technical curiosity—it has real chemical consequences for your coffee.

When coffee experiences elevated temperatures during grinding, it undergoes accelerated oxidation of oils, premature release of volatile compounds, and potential development of bitter compounds. Coffee appears to have a “thermal threshold” around 120°F (49°C), above which negative flavor impacts become increasingly noticeable, particularly in light roasts and specialty beans with delicate flavor profiles.

Understanding how burr heat affects coffee grounds is essential for anyone serious about preserving the intended flavor profile of their beans.

Material Properties: Understanding Steel Burrs

Steel burrs, typically made from hardened alloy steel, possess distinct thermal properties that influence how they interact with your coffee beans during grinding. These burrs feature a remarkably high thermal conductivity—approximately 50 W/m·K—which means they excel at transferring heat away from the grinding zone.

This high conductivity creates a significant advantage: heat generated at the cutting edge rapidly disperses throughout the entire burr assembly and into the grinder body. This efficient heat transfer provides several benefits:

- Prevents concentrated “hot spots” at the cutting edge

- Distributes heat more evenly across the entire grinding mechanism

- Allows for quicker cooling between grinding sessions

- Reduces localized temperature spikes that could affect coffee particles

Steel burrs exhibit a distinct thermal behavior cycle—they heat up relatively quickly at first but then stabilize as heat dissipates through the material. Similarly, they cool down more rapidly once grinding stops, returning to ambient temperature faster than ceramic alternatives.

The durability characteristics of steel also affect long-term heat management. While steel burrs will eventually dull with use (especially when grinding very dark, oily beans), their thermal properties remain relatively consistent throughout their lifespan. Understanding these properties helps you make better decisions when comparing ceramic vs steel burr performance for your brewing needs.

For those interested in experiencing the benefits of steel burrs firsthand, exploring our collection of stainless steel manual coffee grinders provides practical options for temperature-conscious grinding.

Material Properties: Understanding Ceramic Burrs

Ceramic burrs, typically constructed from zirconium oxide, represent a different approach to coffee grinding with unique thermal characteristics. The most notable difference is ceramic’s significantly lower thermal conductivity—approximately 2-3 W/m·K—which is roughly 20 times less than steel. This makes ceramic a thermal insulator rather than a conductor.

This insulating property creates distinct thermal behavior during grinding:

- Heat remains more localized at the cutting edge where bean fragmentation occurs

- Temperature rises more slowly at first but can eventually reach higher localized peaks

- Heat dissipates much more slowly after grinding stops

- The overall burr assembly maintains a more stable temperature during intermittent use

A common misconception is that ceramic burrs “run cooler” than steel—this isn’t technically accurate. While ceramic burrs warm up more slowly, they actually retain heat longer at the grinding surface where it matters most. The heat doesn’t dissipate as readily, potentially exposing coffee particles to elevated temperatures for longer periods.

From a durability perspective, ceramic burrs generally maintain their edge longer than steel, particularly when grinding medium-to-light roasts. However, they’re more brittle and susceptible to damage from foreign objects like small stones that occasionally find their way into coffee beans.

For coffee enthusiasts who appreciate the unique properties of ceramic grinding elements, our selection of ceramic burr coffee grinders offers options designed to balance heat management with grinding precision.

Practical Comparison: Heat Management in Real-World Grinding

When theory meets practice, how do steel and ceramic burrs actually compare in real-world heat management? The following comparison highlights key differences:

| Factor | Steel Burrs | Ceramic Burrs |

|---|---|---|

| Initial heat transfer rate | Fast (conducts heat quickly) | Slow (insulates heat) |

| Heat distribution pattern | Even across burr surface | Localized at cutting edge |

| Temperature at cutting edge during continuous grinding | Moderate (heat dissipates) | Higher (heat accumulates) |

| Recovery time after heavy use | 2-3 minutes | 4-5 minutes |

| Impact on fine grinding (espresso) | Less localized heat exposure | More localized heat exposure |

| Impact on coarse grinding | Minimal difference | Minimal difference |

Different usage patterns significantly affect how heat builds up in either material. Single-dose grinding—where you grind only what’s needed for immediate use—minimizes heat accumulation in both materials. Continuous operation, however, can lead to substantial temperature increases, with ceramic potentially reaching higher localized temperatures at the cutting edge.

The grinding fineness also plays a crucial role. Fine espresso grinding generates significantly more friction and heat than coarse grinding for French press or cold brew. This means material differences become more pronounced when grinding for espresso or Turkish coffee.

Manual versus electric grinding creates another distinction. Hand grinders generally produce less heat regardless of material due to slower grinding speeds and natural pauses in the grinding motion. Electric grinders operate at higher RPMs, generating more friction and heat in less time.

Understanding the comprehensive heat performance comparison between burr materials can help you select the right grinder for your specific brewing style and volume needs.

Impact on Coffee Flavor: Can You Taste the Difference?

The theoretical differences in heat management between steel and ceramic burrs raise an important question: do these differences actually translate to perceptible flavor changes in your cup?

Heat during grinding potentially affects several key flavor components in coffee:

- Volatile aromatic compounds can evaporate prematurely, diminishing the coffee’s aromatic complexity

- Oils can oxidize more rapidly, altering mouthfeel and creating rancid notes

- Certain compounds may undergo accelerated chemical reactions, potentially increasing bitterness

- Delicate flavor notes (particularly floral and fruit characteristics) may become muted or transformed

Not all coffees are equally susceptible to heat-related flavor changes. Light-roasted beans with their higher acidity and delicate floral and fruit notes show the greatest vulnerability to heat damage during grinding. Similarly, single-origin coffees selected for their distinctive flavor profiles may lose their unique characteristics when subjected to excessive heat. Ironically, very dark, oily roasts—while seemingly robust—can also develop increased bitterness when ground at higher temperatures.

Blind tasting results suggest that differences are most noticeable in espresso preparation, where fine grinding generates more heat and the intense extraction process highlights subtle flavor variations. For brewing methods that use coarser grinds, such as French press or pour-over, the differences become less pronounced and may not be perceptible to average consumers.

Professional baristas and coffee competitors often pay close attention to grinder temperature, particularly when preparing espresso. This indicates that at the highest levels of coffee preparation, the flavor differences between ceramic and steel burrs are considered significant enough to influence competition results.

Scenarios Where Material Choice Matters Most

While the differences between steel and ceramic burrs exist in theory, certain practical scenarios make these differences more significant:

- High-volume grinding scenarios: Coffee shops grinding dozens of shots consecutively will experience more substantial heat buildup than home users

- Fine espresso grinding: The increased friction from fine grinding magnifies the thermal differences between materials

- Light-roasted specialty coffees: Delicate flavor compounds in light roasts are more susceptible to heat-induced changes

- Competition or precision brewing: When every nuance matters, the thermal behavior of burrs becomes more relevant

- Grinding in warm environments: Higher ambient temperatures reduce the thermal margin before coffee compounds begin degrading

For home users grinding 20-30 grams once or twice daily, material differences become relatively minor compared to other factors like burr alignment, grind consistency, and bean quality. The thermal differences become more pronounced in commercial settings where grinders might process several pounds of coffee continuously.

Understanding when to prioritize burr material helps make informed purchasing decisions. For most home users, either material performs adequately when used properly. For professionals or enthusiasts preparing heat-sensitive specialty coffees, the choice becomes more consequential.

Our precision manual grinders are specifically designed to minimize heat transfer regardless of material, making them ideal for preserving delicate flavor notes. Additionally, implementing proper heat transfer prevention techniques can further reduce thermal impact during grinding.

Beyond Material: Other Factors Affecting Heat During Grinding

While burr material significantly influences heat management, several other factors can have equal or greater impact on temperature during grinding:

- Grinding speed: Higher RPM dramatically increases friction and heat generation

- Electric grinders operating at 500-1000 RPM generate more heat than manual grinders

Lower speed grinding, even with steel burrs, can produce less heat than high-speed ceramic burrs

Burr design and sharpness: Well-designed, sharp burrs create less friction

- Sharper cutting surfaces require less force to fracture beans

- Better bean flow patterns reduce particle recirculation and repeated grinding

Optimized cutting angles minimize unnecessary friction

Grinder construction: Overall design affects heat dissipation

- Motor isolation from grinding chamber reduces heat transfer

- Ventilation design impacts how effectively heat escapes

- Material and mass of the grinder body influence heat sink capacity

Proper maintenance significantly affects heat generation during grinding. Regular cleaning prevents built-up coffee oils and particles from creating additional resistance. Similarly, proper burr alignment ensures beans are cut efficiently rather than crushed repeatedly, reducing unnecessary friction and heat.

The relationship between burr longevity and heat management reveals that well-maintained burrs not only last longer but also maintain their thermal performance characteristics over time.

Smart Grinding Practices for Minimizing Heat Regardless of Burr Material

Regardless of whether you choose steel or ceramic burrs, implementing these practical strategies can minimize heat impact on your coffee:

Allow cooling time between grinding sessions – For steel burrs, 2-3 minutes is typically sufficient; ceramic burrs may require 4-5 minutes to return to ambient temperature

Embrace single-dosing – Grinding only what you need for immediate use prevents heat accumulation from continuous operation

Clean burrs regularly – Remove coffee oils and particles that increase friction and generate additional heat

Match grind size to brewing method – Using appropriate grind settings reduces unnecessary grinding time and friction

Consider slight bean pre-cooling – Storing beans in a cool (not cold) location can provide a small thermal buffer during grinding

Use pulse grinding for fine settings – Brief pauses during electric grinding allow some heat to dissipate

Check and maintain proper burr alignment – Misaligned burrs create excess friction and hotspots

These simple practices help preserve flavor regardless of your grinder’s burr material, ensuring you extract the best possible flavor from your beans. Proper technique often matters more than burr material alone, especially for home brewing scenarios.

Our collection of manual coffee burr grinders is designed with heat minimization in mind, offering options for temperature-conscious coffee enthusiasts.

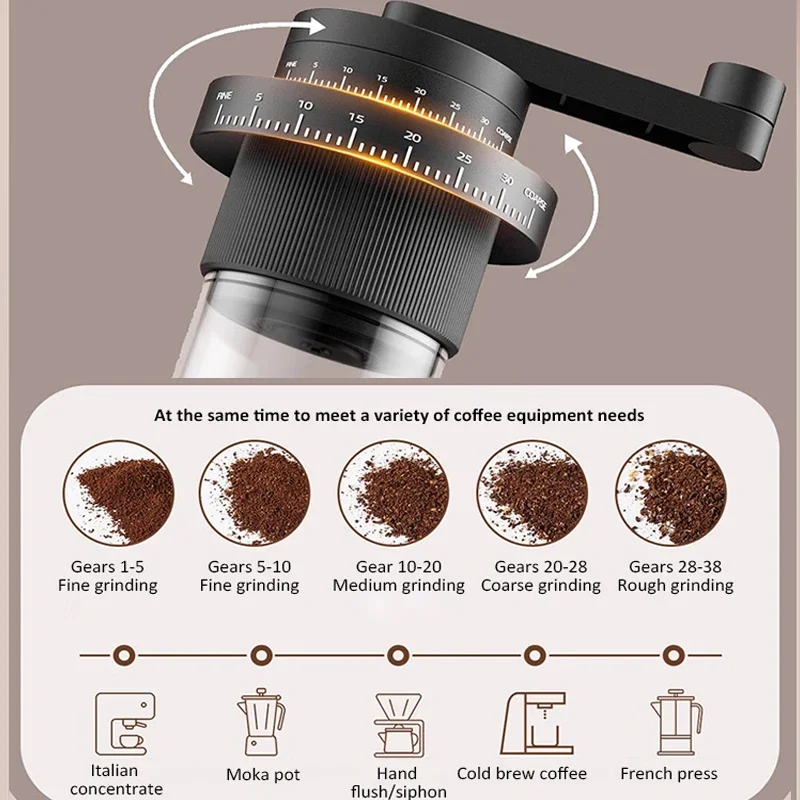

Fine Adjustment Hand Grinder, Precision Manual Grinder, Travel Coffee Grinder

Price range: $185.11 through $494.63 Select options This product has multiple variants. The options may be chosen on the product pageHand Burr Grinder, Hand Crank Coffee Grinder, Manual Espresso Grinder, Portable Coffee Grinder

Price range: $262.72 through $300.22 Select options This product has multiple variants. The options may be chosen on the product pageManual Burr Mill, Manual Coffee Grinder Stainless Steel, Manual Coffee Mill Grinder, Mechanical Coffee Grinder

Price range: $127.26 through $130.32 Select options This product has multiple variants. The options may be chosen on the product pageHand Burr Grinder, Manual Coffee Grinder Stainless Steel, Precision Manual Grinder

Price range: $183.64 through $187.52 Select options This product has multiple variants. The options may be chosen on the product page

Final Verdict: Is Steel or Ceramic Better for Heat Management?

After examining the thermal properties of both materials, we can draw some nuanced conclusions about steel versus ceramic burrs for heat management:

Steel burrs distribute heat more efficiently throughout the entire grinding mechanism, preventing localized hot spots at the cutting edge where coffee particles make contact. This even heat distribution means that while steel warms up faster initially, it’s less likely to expose coffee to extreme temperatures at the precise point of grinding. Steel’s quick thermal recovery also makes it more suitable for back-to-back grinding sessions.

Ceramic burrs, with their insulating properties, warm up more slowly but can eventually reach higher localized temperatures at the cutting surfaces. While this might seem disadvantageous, it actually benefits some usage patterns—particularly intermittent grinding where the slower heat accumulation prevents the burrs from reaching problematic temperatures during short operations.

For high-volume grinding scenarios typical in cafés or larger households, steel burrs generally offer superior heat management due to their efficient heat distribution and quicker recovery times. For home enthusiasts who grind smaller amounts less frequently, either material performs well, with technique often mattering more than material choice.

For espresso preparation, where fine grinding generates more friction and heat, steel’s thermal conductivity provides a slight advantage in preserving delicate flavor compounds. Our selection of manual espresso grinders reflects this consideration, though both materials can excel with proper technique.

Above all, overall grinder quality—including design, manufacturing precision, and burr alignment—often matters more than just the burr material. A well-designed ceramic burr grinder will outperform a poorly designed steel one, and vice versa. When selecting a grinder, consider the best materials for burrs alongside other important factors like grind consistency and adjustment precision.

FAQs About Burr Materials and Heat

Do ceramic burrs really grind cooler than steel burrs?

This is a common misconception. Ceramic burrs warm up more slowly due to lower thermal conductivity, but they can actually reach higher localized temperatures at the cutting edge where beans are ground. Steel burrs distribute heat more efficiently throughout the entire burr assembly, potentially keeping the grinding surface cooler during extended use.

How much does heat actually affect the taste of my coffee?

The impact varies significantly based on coffee type and brewing method. Light-roasted specialty coffees with delicate flavor compounds show the most noticeable changes when ground at elevated temperatures (above 120°F/49°C). For everyday brewing with medium roasts, the differences are more subtle but can still affect overall cup quality, particularly for espresso preparation.

Which burr material lasts longer under regular use?

Ceramic burrs typically retain their edge longer than steel, especially when grinding light-to-medium roasts. However, ceramic is more brittle and susceptible to damage from foreign objects like small stones. Steel burrs are more durable against impacts but may require replacement sooner due to gradual dulling, particularly with dark, oily beans.

Can I measure the heat generated in my home grinder?

Yes, using an infrared thermometer to measure burr temperature before and after grinding provides useful data. Place a thermometer near the burr exit point immediately after grinding to capture the maximum temperature. Temperature increases of 20-30°F (11-17°C) are typical for normal home grinding sessions.

Do specialty coffee shops prefer one material over another?

Professional opinions vary widely. Many specialty shops prefer steel burrs for high-volume scenarios due to better heat distribution and faster recovery times. Some shops specifically choose ceramic for certain coffee types or flavor profiles. The comprehensive comparison between grinder burrs reveals that at the professional level, the choice often depends on specific applications rather than universal preference.