Understanding the Science of Heat Generation in Manual Coffee Grinding

When you grind coffee beans using a manual grinder, you’re not just breaking down beans—you’re participating in a fascinating physics experiment. The primary source of heat during manual grinding comes from friction between the coffee beans and the burrs. As you turn the handle, the mechanical energy from your arm converts into heat energy through friction.

Several key factors influence how much heat builds up during grinding:

- Grinding speed and technique: The faster you grind, the more friction and heat you generate

- Bean characteristics: Harder beans, lower moisture content, and darker roasts typically create more friction

- Burr design and material: Different materials conduct heat differently, affecting how quickly heat builds up or dissipates

- Ambient temperature: Starting with warmer equipment naturally leads to higher grinding temperatures

This heat generation matters because it directly impacts your coffee’s flavor. While manual grinders typically generate less heat than their electric counterparts, understanding how heat works in manual coffee burr grinders helps you make more informed decisions about your grinding approach.

The physics behind this process is straightforward—friction converts kinetic energy into thermal energy. A typical manual grind might increase bean temperature by 10-15°F (5-8°C), compared to 30-60°F (17-33°C) in high-speed electric grinders. This difference might seem small, but it significantly affects the delicate compounds in your coffee beans.

How Heat Impacts Your Coffee’s Flavor Profile

The heat generated during grinding triggers a complex series of chemical changes in your coffee grounds. These changes directly affect what ends up in your cup.

When coffee grounds experience elevated temperatures, the volatile aromatic compounds—the very elements responsible for coffee’s enticing aroma and complex flavor—begin to evaporate prematurely. These compounds are extremely sensitive to temperature changes, with some beginning to degrade at temperatures as low as 86°F (30°C). Once these compounds disappear, they’re gone forever, leaving your coffee tasting flat or one-dimensional.

Heat also affects the oils present in coffee beans. These oils contribute significantly to coffee’s mouthfeel and carry many flavor compounds. When exposed to excess heat, these oils can oxidize more rapidly, potentially introducing bitter or rancid notes to your brew. This is particularly noticeable in coffee prepared for espresso, where heat affects the consistency of your espresso grind and can lead to channeling during extraction.

The extraction parameters also change when brewing with heat-affected grounds. Heat can cause inconsistent particle sizes, which extract at different rates. This leads to some grounds being over-extracted (bitter) while others remain under-extracted (sour), creating an unbalanced cup. For those seeking precision in their espresso preparation, understanding how heat generation affects precision in grind settings becomes especially important.

Key Heat-Related Flavor Issues:

– Loss of aromatic complexity and brightness

– Increased bitterness and astringency

– Diminished fruit and floral notes

– Premature development of “cooked” or flat flavors

– Inconsistent extraction leading to muddled taste profiles

By contrast, grinding with minimal heat buildup preserves these sensitive compounds, resulting in a cup with vibrant acidity, clear flavor notes, and proper aromatic expression. This preservation of flavor is one of the primary reasons coffee enthusiasts often prefer manual grinding despite the additional effort involved.

Grinder Design: How Materials Affect Heat Transfer

A. Burr Materials and Their Thermal Properties

The material of your grinder’s burrs plays a crucial role in managing heat during the grinding process. Different materials have distinct thermal properties that affect how heat is generated and transferred.

Ceramic burrs have gained popularity for their lower thermal conductivity. This means they absorb heat more slowly and are less likely to transfer that heat to your coffee beans during grinding. Quality ceramic burrs and their heat management properties make them a good choice for heat-sensitive coffee enthusiasts, especially those grinding lighter roasts where preserving delicate flavors is paramount.

Steel burrs, while potentially transferring more heat due to higher thermal conductivity, often provide superior cutting ability and durability. Different steel compositions handle heat differently:

- 420 stainless steel burrs offer good corrosion resistance with moderate heat conductivity

- M340 steel provides excellent edge retention with somewhat higher heat transfer

- K-110/D2 tool steel offers exceptional hardness but tends to conduct heat more readily

Many premium grinders use specialized coatings on steel burrs to reduce friction and minimize heat generation. These coatings—often titanium nitride or diamond-like carbon—can significantly improve performance without sacrificing durability. For coffee enthusiasts weighing their options, a deeper dive into how ceramic and steel burrs differ in heat management reveals important considerations beyond simple material differences.

B. Structural Components That Influence Heat

Beyond the burrs themselves, several structural components significantly impact a manual grinder’s heat performance:

The bearing system is particularly important. Dual bearing designs distribute the grinding forces more evenly, reducing wobble and unnecessary friction. High-quality bearings with proper lubrication ensure smooth operation, directly lowering heat generation during use.

Burr alignment plays a critical but often overlooked role in heat management. Perfectly aligned burrs grind efficiently with minimal wasted energy. Even slight misalignment forces burrs to work harder, generating more heat and potentially creating inconsistent grind sizes.

The grinder body material also influences heat performance. Materials with higher thermal mass can absorb and dissipate heat before it affects the beans. Many grinders designed with heat management materials use strategically placed metal components to draw heat away from the grinding chamber.

Some premium manual grinders incorporate specific design elements to manage heat:

– Extended grinder shafts that increase distance between the burrs and bearings

– Ventilated chambers that allow airflow during grinding

– Thermally isolating components that separate heat-generating parts

Comparative Analysis: Heat Generation in Popular Manual Grinder Designs

Different manual grinder designs approach the challenge of heat management in unique ways. Each style offers distinct advantages and considerations when it comes to temperature control during grinding.

| Grinder Type | Heat Management Capability | Burr Size | Bearing System | Grinding Efficiency | Best For |

|---|---|---|---|---|---|

| Traditional | Moderate | Small (40-47mm) | Simple, single bearing | Lower | Occasional use, travel |

| Premium Portable | Good to Excellent | Medium (48-55mm) | Dual bearing, stabilized | High | Daily use, travel, all brew methods |

| Tabletop/Countertop | Excellent | Large (60-80mm) | Advanced, multiple bearings | Very high | Home enthusiasts, small cafes |

Traditional hand grinders typically employ simpler bearing systems that may allow more movement during grinding. This increased movement creates additional friction and heat. Their smaller burrs require more rotations to grind the same amount of coffee, potentially generating more heat through extended grinding time.

Premium portable grinders often feature sophisticated dual bearing systems that significantly reduce wobble. This stability translates directly to less friction and heat generation. Many precision manual grinders with advanced heat management features incorporate stabilizing elements that keep burrs perfectly aligned even under pressure, further reducing unnecessary friction.

The handle design significantly impacts grinding effort and resulting heat. Longer handles provide better mechanical advantage, allowing smoother operation with less force. This reduced effort means less energy converted to heat during grinding. Some advanced models feature counterbalanced handles that maintain momentum throughout the grinding motion, creating a more fluid action that minimizes temperature spikes.

Stability features like non-slip bases or wider bodies help reduce wobbling during operation. By keeping the grinder steady, these features prevent the burrs from working against each other inefficiently, which would otherwise generate excess heat.

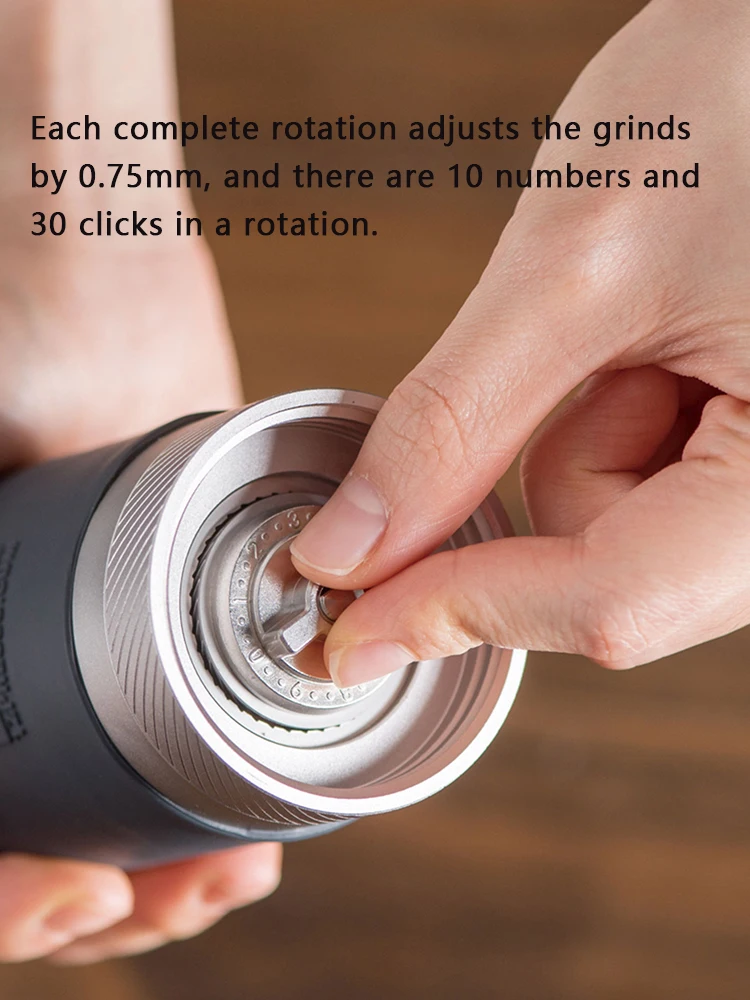

Adjustment mechanisms also affect heat generation. Stepped adjusters with clear detents allow for consistent settings without overtightening, while high-precision stepless systems can be fine-tuned to achieve optimal grinding efficiency for each bean type and brewing method.

Practical Techniques to Minimize Heat During Manual Grinding

A. Optimizing Your Grinding Motion

Proper technique is perhaps the most immediate way to reduce heat generation, regardless of which grinder you own. The ideal grinding motion is smooth, consistent, and performed at a moderate pace.

Start by establishing a steady rhythm rather than grinding as fast as possible. A moderate pace—about one rotation per second—provides the optimal balance between efficiency and heat management. This approach allows burrs to cut beans cleanly without generating excessive friction.

Your hand position and grip technique matter significantly. Hold the grinder body firmly with your non-dominant hand to provide stability. Your dominant hand should grip the handle firmly but not tensely, focusing on smooth circular motions rather than jerky movements. This technique reduces strain on both you and the grinder while minimizing friction-related heat.

Common mistakes to avoid include:

– Grinding too rapidly

– Using inconsistent force throughout the rotation

– Allowing the grinder to wobble excessively

– Applying too much downward pressure

For those focused on precision brewing like espresso, understanding how grinding technique affects heat and ultimately your espresso grind quality becomes essential for consistent results cup after cup.

B. Strategic Approaches for Different Volumes

Single-dose grinding—preparing just enough coffee for one brewing session—is the most effective strategy for minimizing heat accumulation. This approach ensures minimal heat buildup since the grinding process is brief and provides freshly ground coffee for immediate use.

When preparing larger batches, consider dividing your beans into smaller portions and taking short pauses between batches. Even a 30-second rest allows some heat to dissipate from the grinding mechanism. During these pauses, you can gently shake the grinder to release any trapped grounds while allowing air to circulate through the burrs.

The way you feed beans into the grinder also impacts heat generation. Rather than filling the hopper completely, try adding small amounts of beans gradually. This technique reduces resistance during grinding and helps maintain a consistent temperature throughout the process.

Different hand crank designs that help manage heat during manual grinding can make these techniques more effective. Grinders with larger, ergonomic handles reduce the effort required and help maintain the smooth, consistent motion that minimizes heat buildup.

Bean Preparation: The Often-Overlooked Factor in Heat Management

The condition of your coffee beans before they even enter the grinder plays a surprisingly important role in heat generation during grinding. Bean temperature directly affects grinding dynamics—colder beans are slightly more brittle and can fracture more cleanly, potentially reducing the friction and resulting heat during grinding.

Humidity and moisture content also significantly influence grinding behavior. Beans stored in particularly humid environments may contain slightly more moisture, making them tougher and more resistant to grinding. This increased resistance can generate more friction and heat. Conversely, extremely dry beans may produce more fines (very small particles), which can increase surface area for friction.

Fresh versus rested beans behave differently in the grinder. Very fresh beans (1-7 days off roast) contain more CO2 and volatile compounds, which can affect grinding resistance. Many specialty coffee enthusiasts find that beans rested for 7-14 days provide optimal grinding performance with reduced heat generation.

Roast level dramatically impacts grinding behavior:

– Light roasts: Denser and harder, requiring more force and potentially generating more heat

– Medium roasts: Balanced density, typically generate moderate heat

– Dark roasts: More brittle and oily, potentially creating more friction through oil residue

For optimal results, consider storing beans in airtight containers at room temperature or slightly cooler. Many grinders that help manage heat when processing different bean types perform best with beans that have stabilized at a consistent temperature and humidity level before grinding.

Maintenance Practices That Minimize Heat Generation

Proper maintenance of your manual coffee grinder isn’t just about longevity—it directly impacts heat generation and grinding performance. A well-maintained grinder works more efficiently, generating less heat while producing more consistent grounds.

Essential Maintenance Checklist:

- Regular cleaning: Remove coffee oils and fines weekly for daily users

- Burr inspection: Check for alignment and signs of wear monthly

- Bearing assessment: Listen for unusual sounds and test for smooth operation

- Lubrication: Apply food-safe lubricant to appropriate moving parts as needed

- Calibration: Reset your zero-point and check adjustment mechanism regularly

Coffee oils and fine particles build up on burrs during regular use, increasing friction during grinding. These residues can trap heat and impede the burrs’ cutting efficiency. A thorough cleaning every 1-2 weeks (for daily users) helps maintain optimal performance. For detailed guidance, our guide on maintaining your manual grinder for optimal performance and heat management provides comprehensive step-by-step instructions.

Burr alignment is particularly crucial for heat management. Even slight misalignment forces the burrs to work harder, generating more friction and heat. If you notice uneven grounds or increased grinding effort, check your burr alignment by disassembling the grinder and inspecting for proper seating.

Bearings enable smooth rotation of the grinding shaft. When bearings accumulate debris or lose lubrication, they create additional resistance that translates to heat. Listen for unusual grinding sounds and test the movement by turning the handle without beans—it should feel smooth and consistent throughout the rotation.

Properly maintained grinders not only generate less heat but also provide more consistent grind sizes, which directly impacts extraction quality, particularly for espresso where proper maintenance affects grind settings and heat generation.

Testing and Measuring Heat in Your Grinder

Understanding whether your grinder is generating excessive heat begins with simple observation and testing. While you might not have laboratory equipment at home, several practical methods can help you assess your grinder’s temperature performance.

One straightforward approach is the touch test. After grinding a normal dose of coffee (about 20g), carefully touch the burr mechanism and grinding chamber. They should feel only slightly warm—never hot. If you can’t comfortably keep your finger on the burrs, there’s excessive heat generation happening.

For a more precise measurement, you can use a digital instant-read food thermometer. Here’s a simple testing protocol:

- Measure the temperature of your beans before grinding

- Grind a normal dose using your typical technique

- Immediately measure the temperature of the grounds

- Calculate the difference to determine heat increase

A well-performing manual grinder typically shows a temperature increase of only 5-10°F (3-6°C). Anything substantially higher may indicate issues with your grinder or technique.

Other observable indicators of excessive heat include:

– A noticeably “cooked” aroma from freshly ground coffee

– Increased static electricity in the grounds

– Grounds clumping more than usual

– Lighter colored grounds than expected (indicating potential heat discoloration)

For espresso enthusiasts, understanding how heat measurement can help you achieve the correct grind setting is particularly valuable for consistent extraction.

Beyond Heat: Related Factors in Manual Grinding Quality

While heat management is crucial, it exists within an interconnected system of factors that collectively determine grinding quality. Understanding these relationships helps develop a holistic approach to manual grinding.

Grind consistency shares a complex relationship with heat generation. Inconsistent particle sizes increase the likelihood of both under-extraction (from larger particles) and over-extraction (from fines), which can mask the negative flavor impacts of heat. Conversely, excessive heat can cause beans to fracture unpredictably, creating more fines and degrading consistency. Flat burr designs affect heat distribution and grinding quality in distinct ways compared to conical burrs, with each offering different advantages for consistency.

Physical grinding effort correlates strongly with heat generation. The more force required to turn the handle, the more energy is converted to heat through friction. This explains why premium grinders with smooth operation tend to generate less heat—they convert more energy into cutting beans rather than producing heat.

Static electricity, while seemingly unrelated, both results from and contributes to grinding issues. The friction that generates heat also creates static charges, which cause grounds to cling to surfaces and each other. This retention can lead to stale grounds mixing with fresh ones in subsequent uses, potentially affecting flavor.

Environmental factors like humidity and altitude also influence grinding dynamics:

– Low humidity increases static electricity and can make beans more brittle

– High humidity may make beans slightly tougher and more resistant to grinding

– Higher altitudes generally have lower atmospheric pressure, which can affect bean structure and grinding behavior

Fine Adjustment Hand Grinder, Precision Manual Grinder, Travel Coffee Grinder

Price range: $185.11 through $494.63 Select options This product has multiple variants. The options may be chosen on the product pageHand Burr Grinder, Hand Crank Coffee Grinder, Manual Espresso Grinder, Portable Coffee Grinder

Price range: $262.72 through $300.22 Select options This product has multiple variants. The options may be chosen on the product pageManual Burr Mill, Manual Coffee Grinder Stainless Steel, Manual Coffee Mill Grinder, Mechanical Coffee Grinder

Price range: $127.26 through $130.32 Select options This product has multiple variants. The options may be chosen on the product pageHand Burr Grinder, Manual Coffee Grinder Stainless Steel, Precision Manual Grinder

Price range: $183.64 through $187.52 Select options This product has multiple variants. The options may be chosen on the product page

Frequently Asked Questions About Heat in Manual Coffee Grinders

Does grinding speed in a manual grinder significantly affect coffee flavor due to heat?

Yes, grinding speed directly impacts heat generation and subsequently affects flavor. Faster grinding creates more friction and heat, which can degrade volatile compounds in coffee. A moderate, consistent pace typically produces the best results by balancing efficiency with minimal heat generation.

Are ceramic burrs always superior to steel burrs for minimizing heat?

Not necessarily. While ceramic burrs conduct less heat than steel, high-quality steel burrs in well-designed grinders often provide better cutting efficiency with minimal heat generation. The overall grinder design, bearing system, and grinding technique typically have more significant impacts on heat than burr material alone.

How can I tell if my grinder is generating too much heat?

Check if burrs feel uncomfortably hot after grinding, note if coffee aroma changes during grinding (developing “cooked” notes), and observe whether grounds are particularly static-prone or clumping abnormally. These are all indicators of potential excessive heat.

Should I be concerned about heat when grinding for espresso vs. filter coffee?

Yes, especially for espresso. The finer grind required for espresso means more grinding time and potential heat buildup. Heat affects extraction timing when following the 30-second rule for espresso, potentially leading to inconsistent shots. For filter coffee, the effect is less pronounced but still relevant for flavor preservation.

Does the ambient temperature significantly affect manual grinding heat?

Yes. Starting with a grinder that’s already warm (perhaps in a hot kitchen) means you’ll reach higher temperatures during grinding. Similarly, grinding in air-conditioned environments gives you a cooler starting point and typically results in lower final temperatures.

How long should I wait between grinding batches to allow cooling?

For most manual grinders, a 30-60 second pause between batches is sufficient for moderate cooling. If grinding larger volumes, consider 2-3 minute breaks to allow more complete cool-down, especially if your previous batch felt warm.

Are there specific bean types more susceptible to heat damage during grinding?

Light roasted beans, particularly those with delicate floral and fruit notes, show the most noticeable flavor degradation from heat. Single-origin beans with distinctive flavor characteristics tend to demonstrate heat damage more obviously than blends. Understanding the relationship between grind numbers, heat, and espresso quality becomes particularly important when working with these heat-sensitive beans.

Supplementary Content: The Heat Factor in Manual vs. Electric Grinders

The difference in heat generation between manual and electric grinders significantly impacts coffee flavor. This comparison helps explain why many coffee enthusiasts choose manual grinding despite the additional effort involved.

Electric grinders typically operate at much higher speeds—often 500-1,000 RPM for quality burr grinders and up to 20,000 RPM for blade grinders. By contrast, manual grinding happens at approximately 60-120 RPM during normal use. This speed difference fundamentally affects heat generation, with electric grinders typically producing 3-5 times more heat than manual methods.

The duration of grinding also differs significantly. An electric grinder might process a standard 20-gram dose in 5-10 seconds, while a manual grinder typically takes 30-60 seconds. However, the intense heat spike from electric grinding often causes more flavor degradation than the gentler, more prolonged warming during manual grinding.

Design differences also play a crucial role in heat management. Many electric grinders feature motors in close proximity to the burrs, adding motor heat to friction heat. Manual grinders rely solely on human power, without this additional heat source. Comparing heat management in manual versus automatic grinding systems reveals these fundamental differences in approach and outcome.

For particularly heat-sensitive applications like grinding for espresso or light-roasted single-origin coffees, manual grinding offers a significant quality advantage by preserving volatile compounds that would otherwise be damaged by the rapid heating in electric grinders.

Taking Your Manual Grinding to the Next Level

Once you’ve mastered the fundamentals of heat management in manual grinding, several advanced techniques can further elevate your coffee experience:

- Pre-cooling your grinder: For particularly heat-sensitive beans, consider placing your disassembled grinder (without beans) in the refrigerator for 10-15 minutes before grinding

- Double-dose technique: Use half doses with a brief pause between them, even when preparing a single cup

- Rhythm training: Practice maintaining a perfectly consistent grinding pace using a metronome app

- Bean staging: Allow beans to rest at room temperature for 10-15 minutes after removing from storage before grinding

For different brewing methods, consider adapting your approach to optimize results. Espresso benefits from the coolest possible grinding to preserve oils and compounds essential for crema formation. Understanding how advanced heat management techniques affect grind size consistency becomes particularly valuable for espresso preparation.

Pour-over methods typically require a middle-range grind where consistency is more important than absolute temperature control. Still, cooler grinding will preserve the delicate high notes in lighter roasts.

Cold brew, despite using room temperature or cold water for extraction, still benefits from cool grinding to preserve volatile compounds that contribute complexity to the long extraction process.

Seasonal adjustments also impact grinding performance. In summer months, consider grinding in the coolest part of your kitchen and potentially introducing brief pauses during grinding. In winter, you might find that cooler ambient temperatures naturally improve your grinder’s performance.

With careful attention to heat management and achieving the perfect grind setting by controlling heat factors, you’ll discover new dimensions of flavor that may have previously been masked by heat-related issues.

At Savor Suite, we believe that proper heat management represents one of the most overlooked yet impactful aspects of coffee preparation. By applying these principles to your daily coffee ritual, you’ll unlock new levels of flavor complexity and consistency in every cup.