Precision Manual Grinder

Need ultimate precision for metal parts? Our manual grinders offer direct control to achieve exceptionally flat surfaces, sharp custom tools, and superior finishes through hands-on craftsmanship.

Showing all 7 results

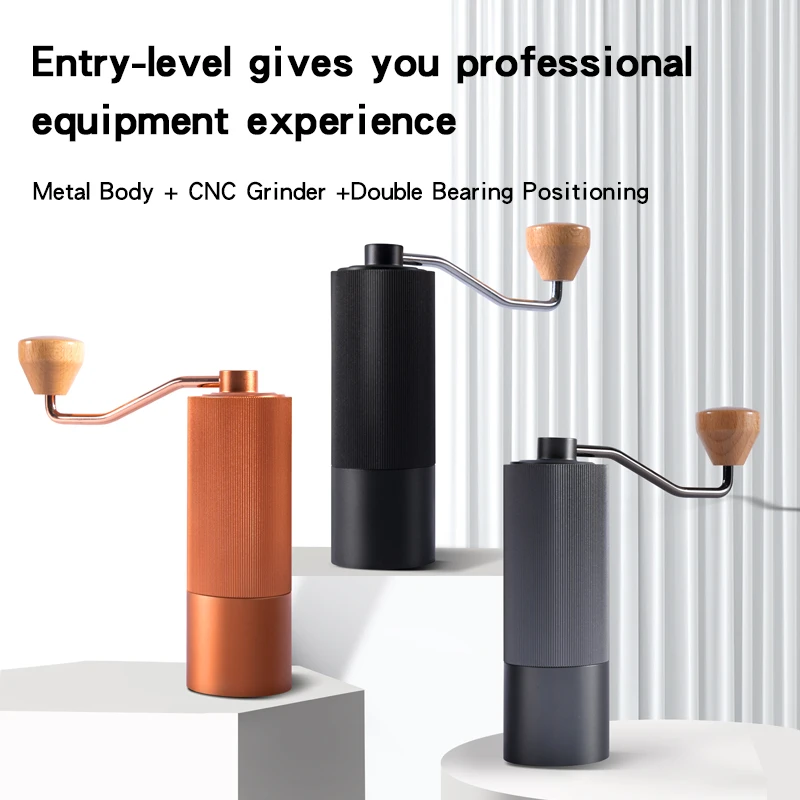

Fine Adjustment Hand Grinder, Precision Manual Grinder, Travel Coffee Grinder

Price range: $313.00 through $377.20 Select options This product has multiple variants. The options may be chosen on the product pageHand Burr Grinder, Manual Coffee Grinder Stainless Steel, Manual Espresso Grinder, Precision Manual Grinder

$462.74 Select options This product has multiple variants. The options may be chosen on the product pageHand Burr Grinder, Manual Espresso Grinder, Precision Manual Grinder, Travel Coffee Grinder

Price range: $322.86 through $353.57 Select options This product has multiple variants. The options may be chosen on the product pageHand Burr Grinder, Manual Coffee Grinder Stainless Steel, Precision Manual Grinder

Price range: $183.64 through $187.52 Select options This product has multiple variants. The options may be chosen on the product pageFine Adjustment Hand Grinder, Precision Manual Grinder, Travel Coffee Grinder

Price range: $185.11 through $494.63 Select options This product has multiple variants. The options may be chosen on the product page

Showing all 7 results

Understanding Precision Manual Grinders: Artistry in Metalwork

Precision manual grinders represent the perfect marriage of traditional craftsmanship and modern precision requirements. These specialized tools enable artisans to achieve micron-level accuracy through skillful hand operation, delivering results that can reach within 0.0001 inch (2.5 microns) with expert handling.

Unlike automated systems, manual grinders provide immediate tactile feedback that connects the craftsperson directly to their work. This sensory connection, similar to how fine adjustment hand grinders enhance coffee preparation, allows for minute adjustments that machines simply cannot replicate. Each movement translates directly into material removal, creating an intuitive relationship between operator and tool.

The beauty of precision manual grinding lies in how the outcome directly reflects the skill of the operator. As expertise develops, so does the quality of work produced, establishing grinding as both a technical process and an art form that rewards dedication. At Savor Suite, we appreciate this dedication to craft, whether in metalworking or coffee preparation.

Distinctive Features of Premium Precision Manual Grinders

Premium manual grinders distinguish themselves through several key features that elevate their performance:

- Heavy Cast Iron Construction: Substantial bases and frames provide vibration dampening capabilities essential for achieving mirror-like finishes

- Precision-Ground Dovetail Ways: These enable accurate linear movement, ensuring the grinding head travels perfectly straight with minimal deviation

- Micrometer Dials: Calibrated to 0.0001″ increments, allowing for predictable, repeatable material removal

- Hand-Scraped Bearing Surfaces: Meticulously prepared to achieve superior flatness and smooth operation

- Premium Spindle Designs: Engineered with minimal runout (less than 0.00005″), comparable to the precision found in all-metal hand grinders used by coffee enthusiasts

- Multi-Axis Adjustment: Capabilities that allow complex geometries to be ground with precision

- Superior Work-Holding Systems: Including magnetic chucks and precision vises that maintain workpiece position with absolute stability

These features combine to create tools capable of transforming rough materials into components with exceptional accuracy and surface finish.

Exploring the Range: Types of Precision Manual Grinders

Manual Surface Grinders

Designed specifically for creating flat, parallel, and square surfaces, these workhorses form the foundation of precision grinding. They excel in toolmaking applications where true surfaces are essential.

Tool and Cutter Grinders

Specialized for fabricating and resharpening cutting tools, these grinders feature complex adjustments that allow sharpening of complicated geometries including end mills, drills, and form cutters.

Cylindrical Grinders

Available in external and internal varieties, these precision machines can produce perfectly round components with exceptional concentricity, ideal for precision shafts and bearing surfaces.

Jig Grinders

The pinnacle of manual precision, jig grinders allow for intricate contours and precisely located holes, functioning similarly to how flat burr hand grinder designs achieve consistency in coffee preparation.

Critical Components That Determine Grinding Quality

The performance of any precision manual grinder depends on several key components:

- Grinding Wheel Composition: Materials, bond types, and grain sizes determine cutting characteristics and finish quality

- Spindle Assembly: The heart of the grinder, where precision bearings minimize runout for consistent results

- Base and Column Construction: Provides the foundation for stability and vibration control

- Manual Control Mechanisms: Handwheels, feeds, and stops that translate operator input into precise movements

- Workholding Systems: Securing the workpiece with absolute rigidity prevents unwanted movement

- Coolant Delivery Systems: Essential for temperature control and chip removal during operation

Each component plays a vital role in achieving the exacting tolerances and surface finishes that define quality grinding work.

Performance Attributes: What Sets Superior Models Apart

When evaluating precision manual grinders, several performance factors distinguish exceptional models:

- Surface Finish Capabilities: From initial rough grinding (32 Ra) down to mirror finishes (0.5 Ra)

- Achievable Tolerances: Superior models maintain consistency within 0.0001″ over extended operations

- Repeatability: The ability to produce identical results across multiple workpieces

- Vibration Characteristics: Lower vibration translates directly to improved surface quality

- Control Responsiveness: The direct feel and feedback, similar to manual burr mills but with industrial precision

- Material Versatility: The capacity to work effectively across hardened steels, tool steels, and exotic alloys

Selection Criteria: Finding Your Ideal Manual Grinder

When selecting a precision manual grinder, consider these factors to match your specific requirements:

- Required Accuracy: Determine the tolerances your work demands

- Workpiece Dimensions: Ensure the grinder can accommodate your typical parts

- Workspace Considerations: Assess available floor space and weight capacity

- Table Travels: Verify the working envelope meets your project needs

- Accessory Compatibility: Check availability of workholding options and grinding wheels

- Construction Quality: Look for hand-scraped ways and robust castings, similar to evaluating stainless steel manual coffee grinders for durability

- Control Ergonomics: Test the feel of handwheels and adjustments for comfort during extended use

Essential Accessories That Enhance Grinding Precision

To maximize your manual grinder’s capabilities, consider these key accessories:

- Wheel Dressing Tools: Diamond dressers and truing devices for maintaining wheel geometry

- Measurement Tools: Precision indicators, micrometers, and gage blocks for verifying results

- Specialized Fixtures: Sine plates, angle plates, and precision vises for complex setups

- Balancing Equipment: For minimizing vibration in grinding wheels

- Maintenance Supplies: Way oil, stones for removing burrs, and cleaning materials

Is a Manual Precision Grinder Right for Your Workshop?

Q: When should I choose manual over CNC grinding?

A: Manual grinding offers advantages in one-off precision work, teaching fundamentals, and situations requiring operator feel and judgment.

Q: What space requirements should I consider?

A: Most precision manual grinders need 30-50 square feet plus clearance for operation, with robust floor support for weights often exceeding 1,000 pounds.

Q: What skill level is required?

A: While beginners can achieve basic results, developing true precision skills takes practice—similar to mastering mechanical coffee grinders where technique improves with experience.

Q: How do manual grinders compare cost-wise?

A: Quality manual grinders represent significant investments but generally cost substantially less than comparable CNC equipment while offering decades of service when properly maintained.